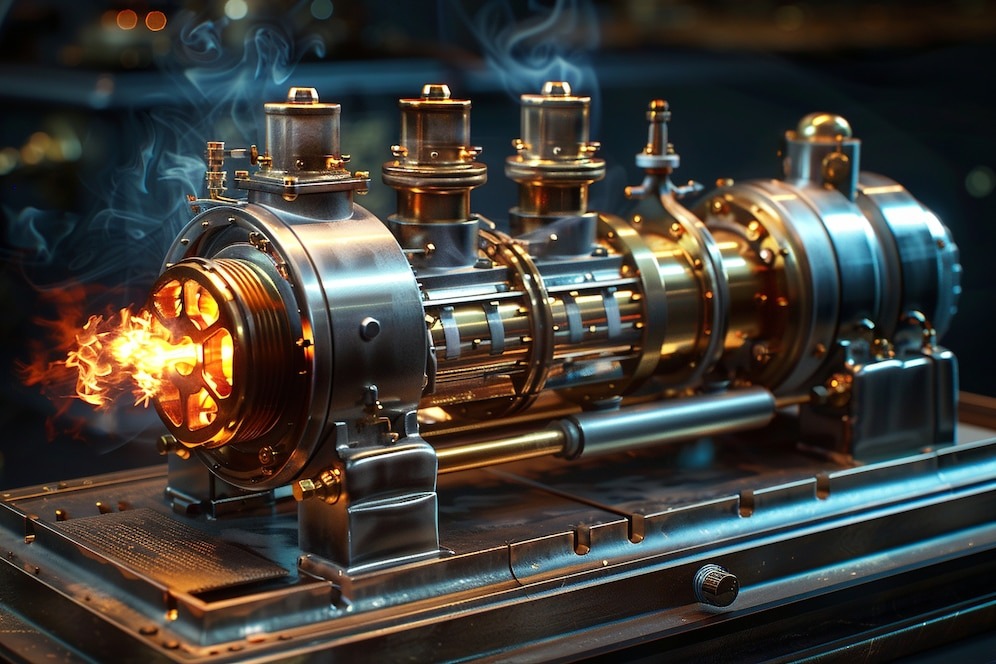

Casting

Sand Casting

- Suitable for low to medium production volumes

- Wide range of alloys and part sizes

- Cost-effective for large or complex parts

Die Casting

- Excellent dimensional accuracy and surface finish

- Ideal for high-volume production runs

- Suitable for complex geometries and thin walls

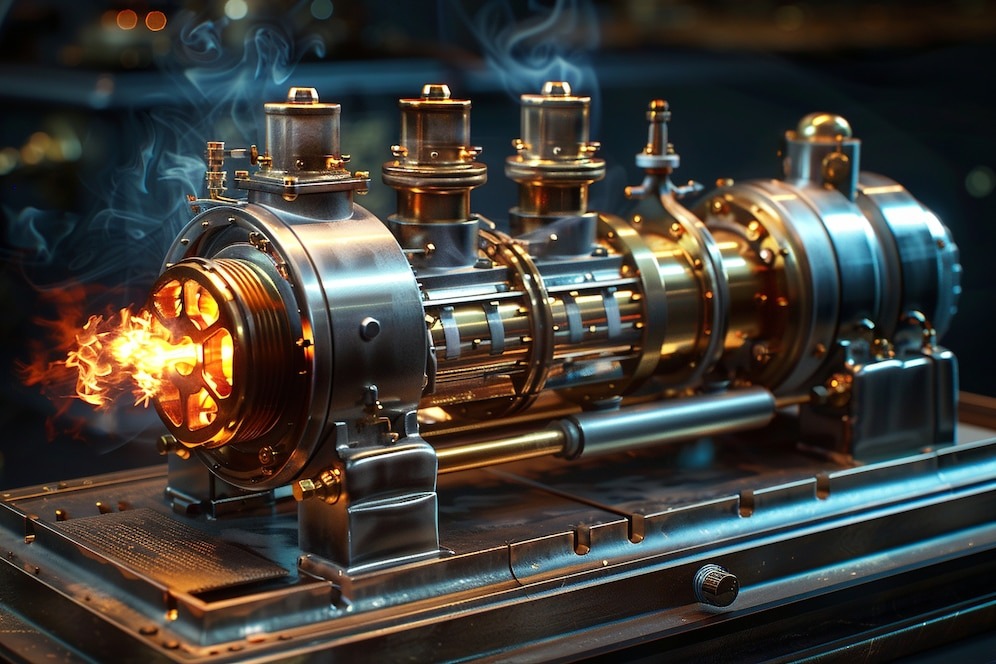

Investment Casting

- High accuracy and excellent surface finish

- Ability to cast complex shapes and intricate details

- Wide range of alloys available

Printing Integrated Investment Casting

- 3D printed patterns replace traditional wax patterns

- Faster turnaround times for prototypes and small batches

- Enables design optimization and complex geometries

- Ideal for aerospace, medical, and other high-precision industries

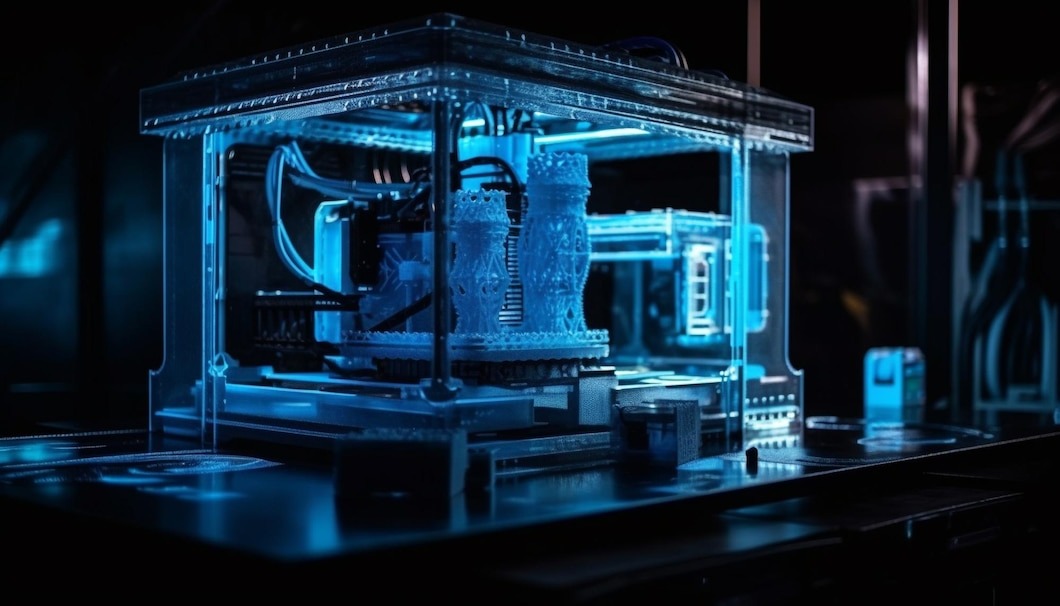

3D Printing

Direct Metal Laser Sintering (DMLS)

- High-precision metal parts

- Wide range of metal alloys available

- Ideal for complex geometries and internal features

Selective Laser Melting (SLM)

- Fully dense metal parts

- Excellent mechanical properties

- Suitable for functional prototypes and end-use parts

Materials

- Aluminum alloys

- Stainless steel

- Titanium alloys

- Cobalt chrome

- Inconel

Applications

- Rapid prototyping

- Low-volume production

- Custom tooling and fixtures

- Complex assemblies

- Lightweighting and part consolidation

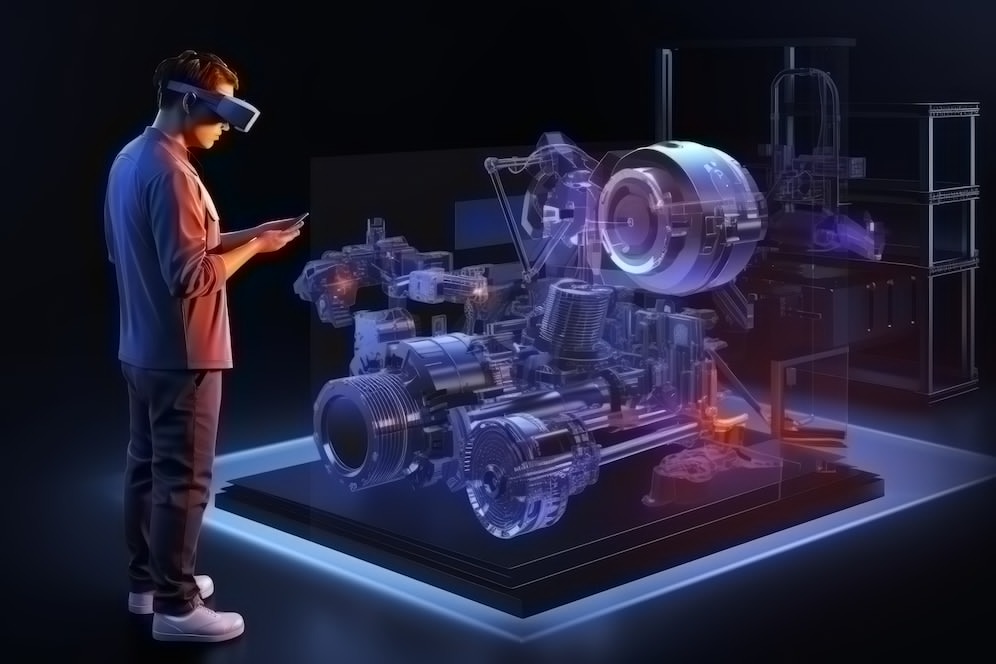

Rapid Prototyping

- Concept Validation: Quick turnaround on proof-of-concept models

- Functional Prototypes: Fully functional prototypes for testing and validation

- Iterative Design: Rapid iteration capabilities for design refinement

- Multi-material Prototyping: Combining different materials for complex prototypes

Advanced Prototyping Techniques

- Hybrid Manufacturing: Combining additive and subtractive processes for optimal results

- Topology Optimization: Utilizing AI-driven design for lightweight, high-performance parts

- Reverse Engineering: Recreating and improving existing parts or products

- Virtual Prototyping: Using advanced simulation tools for digital validation

Cost Management

Product cost Management

- Comprehensive cost analysis to identify savings opportunities

- Strategic sourcing to optimize procurement expenses

- Cost forecasting and budgeting for improved financial planning

- Product lifecycle cost management to enhance profitability

- Implementation of cost control measures to reduce waste

Competitor Benchmarking

- Analysis of competitor pricing strategies to inform your pricing model

- Evaluation of competitors' product features and benefits

- Assessment of market positioning and branding strategies

- Monitoring of competitor marketing tactics and outreach efforts

VAVE

- Systematic approach to improving product value by assessing functions

- Identification of unnecessary costs without impacting quality

- Collaboration with cross-functional teams for comprehensive insights

- Development of innovative solutions to enhance functionality

- Implementation of cost-effective materials and processes